Tetramix

TETRAMIX static mixers are designed for mixing liquids with liquids, liquids with suspensions, solid particles or powdery materials, materials, and gases, gas or gases.

Tetramix type static mixers

Standard TETRAMIX mixers The TETRAMIX static mixer is a device designed for mixing media of the same or different states, especially liquids with liquids, liquids with suspensions, solid particles or powdery substances, materials, as well as gases, gas or gases.

|

|

Its built-in special elements divide and combine the material flow into four parts, then divide it again and again into four parts, mixing the material flow so that each element quadruples the number of previous divisions, e.g. 12 elements mathematically create more than 16.7 million divisions and their variations. The divisions are optimized by four spindle-shaped vortex currents formed directly after the mixing element, resulting in "tunnel-free," space-filling, perfect mixing. |  |

Thus, two different mixing mechanisms operate simultaneously, with the dominant mixing form being determined by the material properties of the media to be mixed, e.g. density, viscosity, temperature, etc. A special feature of the TETRAMIX static mixer is its unique ability to combine the partial vortex flows with direct fluid flow collision. |  |

The TETRAMIX static mixer meets the general requirements for such equipment. Its versatility is supported by other useful features such as

- large free flow cross-section,

- mixing elements with a solid, rigid, impact-resistant design,

- flexible modification of the shape, form and size of the mixing element,

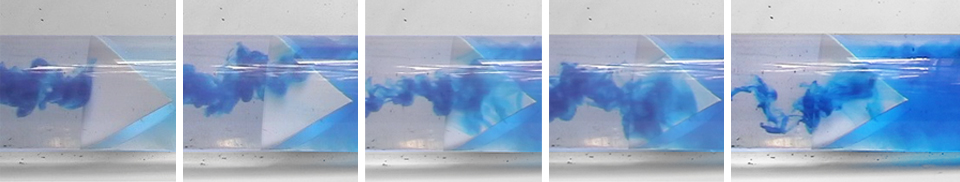

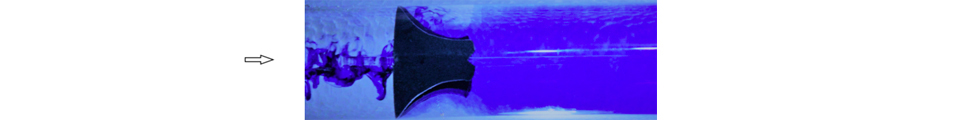

TETRAMIX static mixing element formation of chemical jets in front of the mixing element, their mixing in a transitional zone (quasi-turbulent) flow

TETRAMIXC and TETRAMIXCi mixers

The TETRAMIXC type static mixer is practically identical to the standard TETRAMIX static mixer in terms of flow pattern and all other characteristics, but the enlarged vortex chambers of the mixing elements provide additional benefits.

One of the most useful features is that it can smooth out the intermittent flow pattern of chemical plugs fed intermittently in front of the mixer, making it virtually continuous, while ensuring perfect mixing.

The TETRAMIXCi mixing element is a modified version of the TETRAMIXC mixing element, which, thanks to its curved geometry, further enhances the mixing design variability that is essential for optimizing mixing tasks.

This variability allows the pressure loss during mixing to be adjusted to the current requirements.

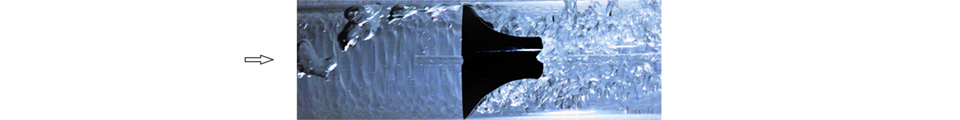

Mixing formation demonstrating maximum utilization of the enlarged vortex chamber:

Mixing of a TETRAMIXCi mixing element with transitional zone flow (gas-liquid)

The above image clearly shows the excellent functioning of the special internal vortex chamber, which is able to immediately mix gas bubbles introduced at a single point and spread them across the entire cross-section after they have been broken up.

The following snapshot shows an example of liquid mixing:

The flow image illustrating the mixing format corresponds to the parameters v~0.33 m/s; Re~20,500 and CoV<0.04.

The same mixing formation is obtained when mixing gases, only with significantly more intense velocity components, high Reynolds numbers and mixing efficiency.

The velocity components of the eddies creating the mixture remain guaranteed after the mixer, as a function of the average velocity, over a straight path length of at least 5-10D.